Oden Pot for Local Restaurant

Requested by a local restaurant ODEN Kozo, we crafted a custom oden pot, harnessing the exceptional heat onductivity of copper to create an authentic and .avorful oden cooking experience.

SCROLL

THE AGING OF COPPER AND WABI-SABI

As a company that has been making copper products for over 400 years, we at Tazen believe that copper products are something that are best enjoyed by “nurturing over time.” The surface of copper products start to change due to chemical reactions immediately after they are put to use; however, the true beauty of copper is found in the changes that is sometimes considered degradation. As you continue to use our copper products and witness the developing expression of the copper over time, we hope that it will inspire you to enjoy the spirit wabi: appreciating the changes to the material over time.

- Japanese copper artisans called akagane-shi (銅師) make each piece by hand

- Hammer tones called arashi (アラシ) are made with tools which have been passed down for hundreds of years

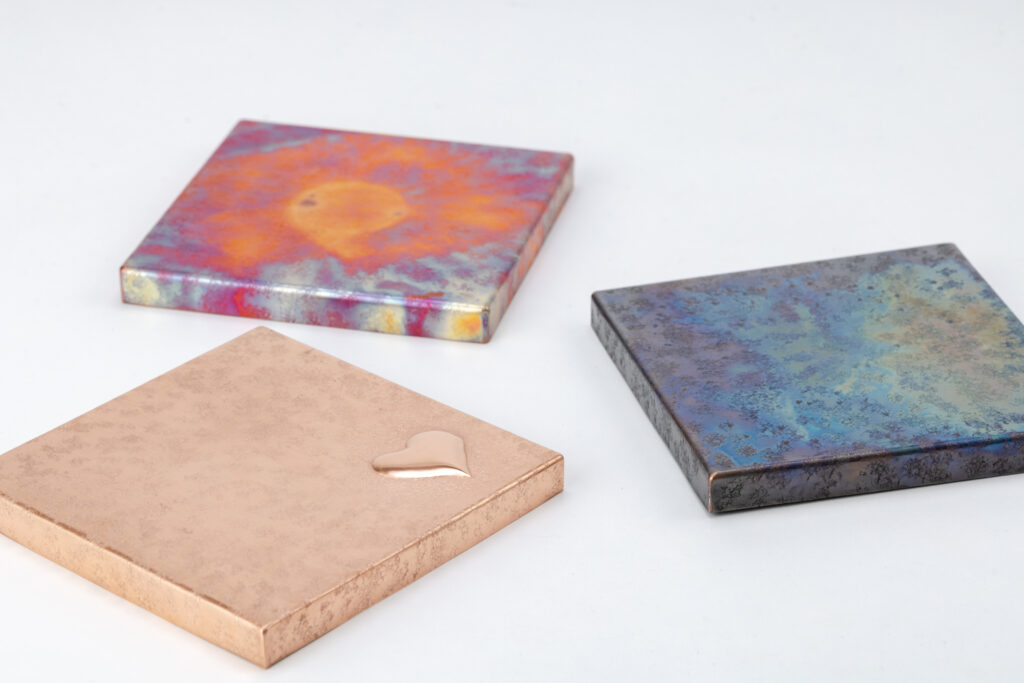

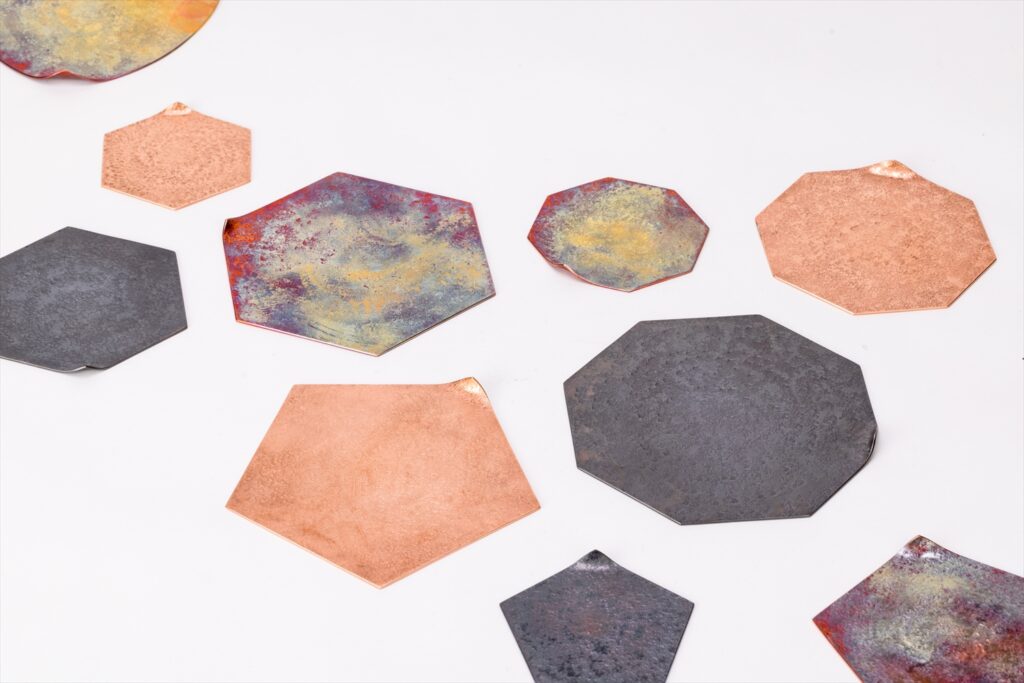

- We suggest three types of finishes: [素-So] [炎-En-] [炎染-Ensen]

- We value the concept of wabi-sabi, the anticipation and appreciation of natural changes to the material over time

In Japan, the process of shaping copper by hammering is called uchidashi. At Tazen, we use hammers and ategane (iron stakes used as a base) that have been passed down for hundreds of years. Skilled artisans hammer the surface one by one using these tools to create a unique textured pattern on the copper known as arashi.

As an option, it is possible to engrave various motifs on the panel.

- We reproduce the traditional techniques of kazari-shokunin, the artisans who created decorative elements for Japanese castle gates.

- In addition to traditional Japanese patterns, we can accommodate a wide range of symbols and other motifs.

The character for So means natural state. With this method, nothing is done to the product other than physical processes such as hammer tone and bending. Enjoy the copper's natural texture, presence, and nurture it from scratch.

En is a finishing method where a copper plate is heated with a flame. With this primordial processing method, rainbow-like color patterns of red and yellow emerge on the surface by putting the oxide film in the fire. Enjoy the changing expression of the copper, reflecting the flickering of the flame.

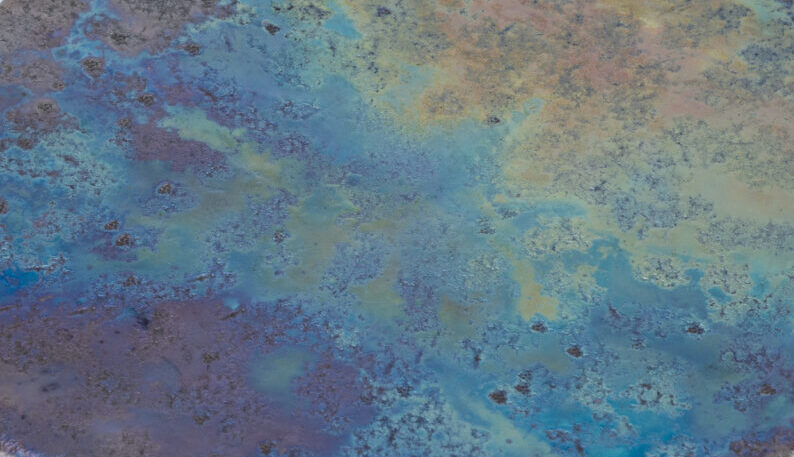

This finish combines the Sen technique-where a sulfurized film is applied to the copper surface using a potassium sulfide solution to dye it jet black-with the En technique, which heats the copper with flame to create an oxide film for coloring. The result is a unique surface featuring deep blue and green rippling patterns.

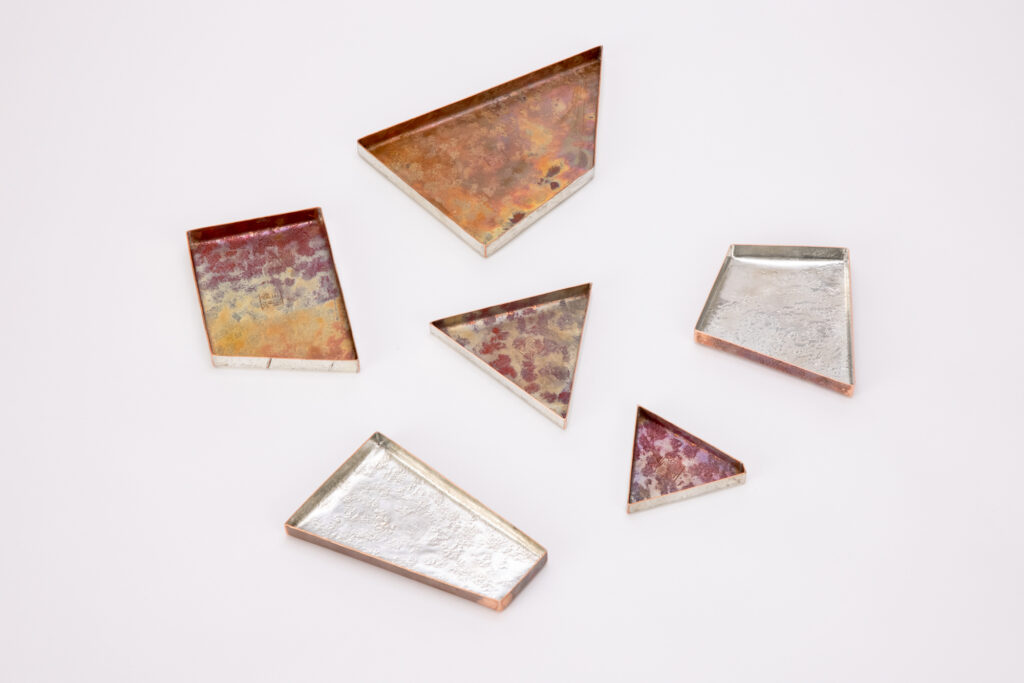

To give hammer-tone and engraving a more sculptural appearance on wall surfaces and to allow flexible layout, we provide a cassette-type system. The pieces are displayed by fixing them directly to the substrate using screw-mounted hooks or by suspending.

For gift protection and packaging, we provide tra- ditional Japanese paulownia wood boxes (Kiribako)

THE AGING OF COPPER AND WABI-SABI

As a company that has been making copper products for over 400 years, we at Tazen believe that copper products are something that are best enjoyed by “nurturing over time.” The surface of copper products start to change due to chemical reactions immediately after they are put to use; however, the true beauty of copper is found in the changes that is sometimes considered degradation. As you continue to use our copper products and witness the developing expression of the copper over time, we hope that it will inspire you to enjoy the spirit wabi: appreciating the changes to the material over time.

- Japanese copper artisans called akagane-shi (銅師) make each piece by hand

- Hammer tones called arashi (アラシ) are made with tools which have been passed down for hundreds of years

- We suggest three types of finishes: [素-So] [炎 -En-] [染-Sen]

- We value the concept of wabi-sabi, the anticipation and appreciation of natural changes to the material over time

The process of shaping copper through hammering is called uchidashi in Japanese. ON-AKAGANE products are made by skilled ar- tisans who hammer the copper at a traditional work station made of wood with large iron fittings called an ategane, using tools that have been passed down for hundreds of years. The arashi hammer textures are hand-hammered one by one, making each piece one of a kind.

The Chinese character for "So" means "natural state." With this method, nothing is done to the product other than physical processes such as hammer tone and bending. Enjoy the copper's natural texture, presence, and nurture it from scratch.

En is a finishing method where a copper plate is burned with a flame. With this primordial processing method, rainbow-like color pat- terns of red and yellow emerge on the surface by putting the oxide film in the fire. Enjoy the changing expression of the copper, reflecting the flickering of the flame.

Sen is a finishing method that is used to dye the copper black by applying a sulfurized film on the surface of the copper plate with a potassium sulfide solution. If "En" is born from fire, "Sen" is born from water. Nurturing starts from restrained texture-Sen is often described as a finish for connoisseur.

Through the technique of annealing - heating at high temperatures and cooling slowly - copper crystals become homogeneous. During this process, the thickness of the oxide film creates a unique contrast where a vivid aka (bright red) appears within the dark brown black on the surface, painting a one-of-a-kind pattern born from chance.

Douko, which literally translates as “copper pot,” is a Japanese word for copperware that is used to boil water with a heat source, often attached to the side wall of a stove or buried in the ash of a brazier.

Initially, it was a simple tool to boil water in a brazier, but various functions were gradually added, such as cooking ingredients, and it became an integrated kitchen system of the Edo period. In the early 20th century, the Sendai Douko, produced by Tazen in Sendai, became popular throughout Japan. We are revisiting this Sendai Douko tradition as contemporary take on copperware to deepen our understanding of the beloved “copper pot” and its essence.

A pot designed speci.cally for the Seri hot pot, a dish that uses the local specialty Seri (Japanese parsley) from sendai

A series of sake ware with geometric motifs, such as cir¬cles and polygons. The unique characteristics of copper enhance the taste of the sake.

A paper knife/wagashi knife whose design was inspired by the signature crescent moon symbol on the front of Masamune Date’s helm.

Random polygon-shaped small boxes that each have a unique shape.

Copper plates with simple designs, made of hammered square copper sheets. You can enjoy various expressions depending on the surface finishing method used.

Composed of soft curves, items in

Hibino Dougu blend well with your

interior designs and enrich your everyday

life.

Making the most of copper’s properties and being handmade, Tazen has produced numerous made-to-order copper items, from traditional decorations for a signi.cant historical building to cooking tools for culinary professionals. Feel free to inquire us about anything if you have something in mind.

Requested by a local restaurant ODEN Kozo, we crafted a custom oden pot, harnessing the exceptional heat onductivity of copper to create an authentic and .avorful oden cooking experience.

Tazen is leading a copper revival in Sendai and beyond through a variety of collaborations with restaurants, sake breweries, artists, and community events.

Tazen's master copper craftsman, Zen Tanaka, collaborated with internationally acclaimed artist and shoemaker Misawa Noriyuki from Sendai to create a stunning artwork titled 'Masamune.' This exceptional piece is entirely crafted from copper and draws inspiration from Date Masamune, the prominent feudal lord of Sendai.